RTIS

In production lines, it is important to see in real time how the individual production is running and whether unpredictable complications have occurred by chance. For this purpose, the RTIS application was created.

Introduction

Rakona s. r. o. belongs to the Procter & Gamble group and produces washing powders and detergents. It has its own production line for each product. The goal of every manufacture is to maximize production and minimize downtime. The lines are automated and have many sensors that collect data from the entire production process. It is these data that are the input to our application for monitoring production lines.

Challenges

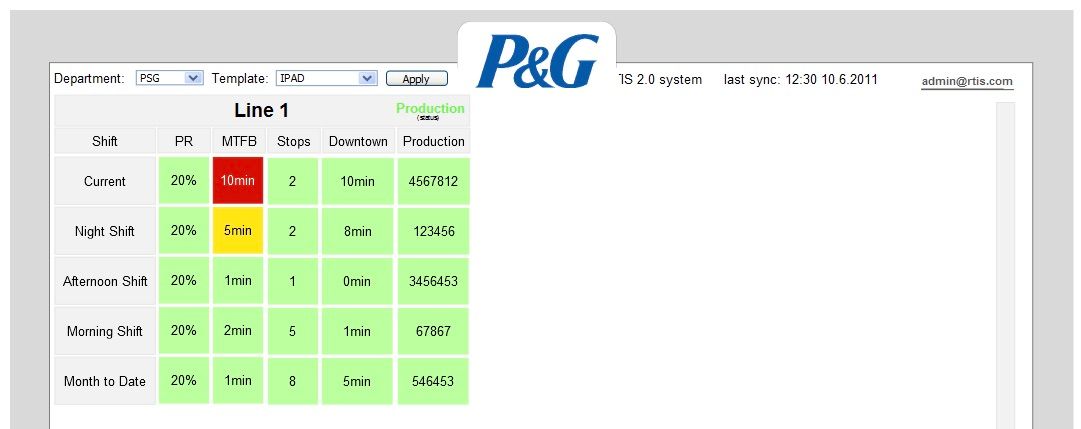

It was necessary to create a simple application that would display the current data from the production lines clearly, so based on this dates would be possible to find out what the current situation was. At the same time, the goal for the application was to work with the database in general, so that when changing data, all you had to do was reconfigure the application and it was not necessary to reinstall it. Emphasis was also placed on the reliability of the display, because poor visualization of production can lead to large financial losses.

Solution

A universal information system was created, providing an up-to-date overview of information from data stored in the company's database. It is a web application that is responsive and therefore works without problems on a tablet, computer or television. The system clearly displays the status of production lines. For each attribute on the dashboard, it is possible to set simple rules for display or conditional formatting. So that key information is displayed clearly and concisely. The application is built on the PHP framework Nette and uses an MSSQL database.

Results

We delivered the application, including all documentation, so that P&G continues to manage the application itself. Our display dashboard is located in several places in the factory, so that key data is always in sight. Imaging devices with our application are located right at the entrance, in the corridors, in the dining rooms and, of course, in the production hall.

The company was so satisfied with the application that RTIS spread to other countries. For example, to the Turkish factory. (Due to the fact that the application is universally written, it is not a problem to connect it to any factory with minor modifications).